Filling Process Products + Tools

Enpro provides patented state of the art high speed RFID traceable components and systems to reduce waste and downtime associated with the filling process. Our services and full product line of traceable vent tubes and tools allow owners and operators to reliably and accurately detect malfunctions during the filling process.

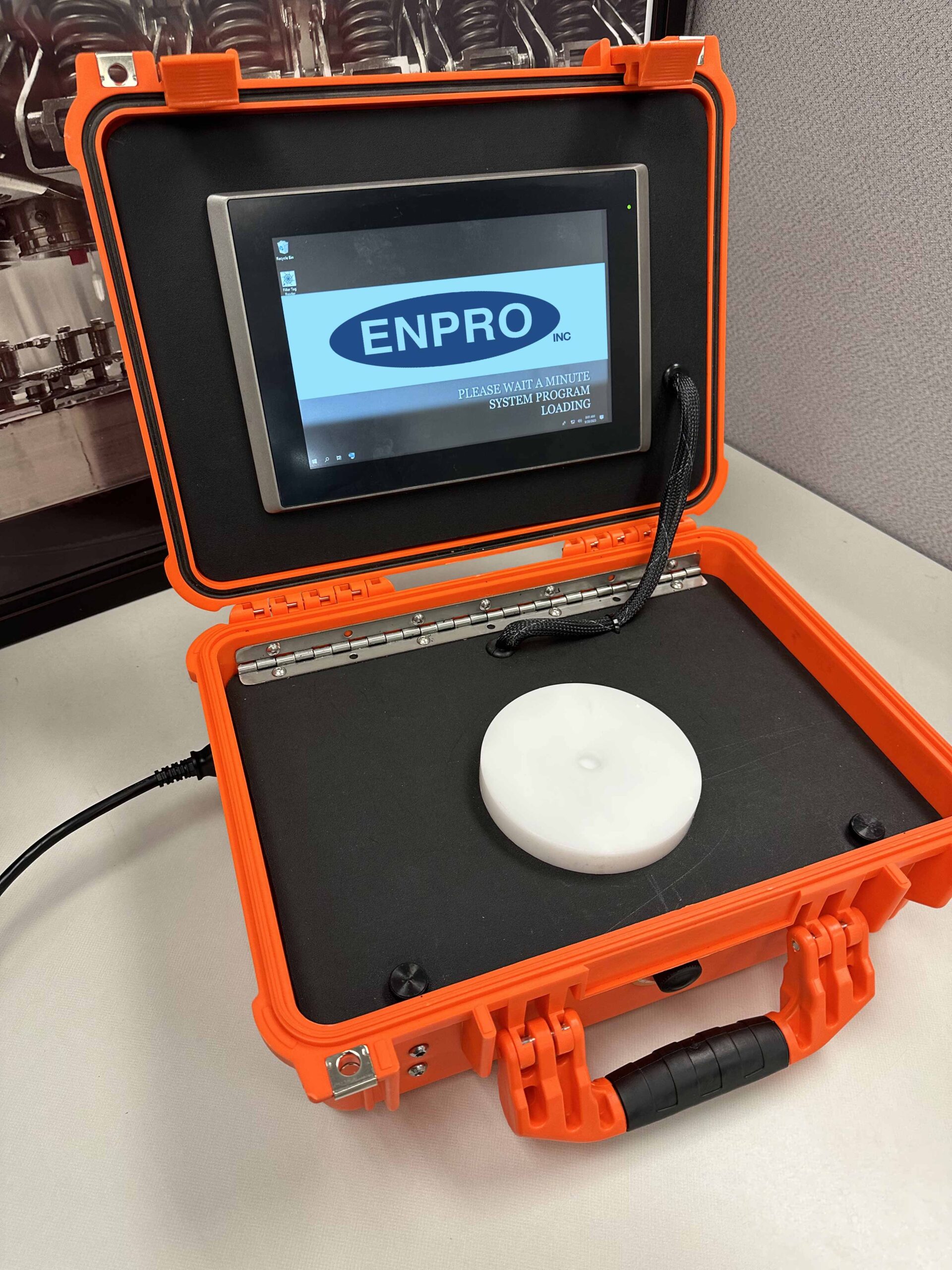

Enpro Filler Vent Tube Reader

Enpro Filler Vent Tube Reader (FVTR/TS)

The Enpro Filler Vent Tube Reader Touch Screen (FVTR-TS) is a high-speed RFID reader that records each RFID tag present in the filler vent tubes or traceable pills in real-time during the filling process.

Click Here for FVTR documents + resources.

Enpro Vent Tube Detection System

The Enpro Vent Tube Detection System (VTDS) is a patented state of the art technology to sense vent tube malfunctions that occur during the filling process.

When the VTDS is used in conjunction with the Enpro Traceable Vent Tubes, vent tube malfunctions can be accurately and reliably detected.

The VTDS consists of two Sensor Detection Assemblies which are mounted on either side of the packaging conveyor. The system provides the operator both a visual and discrete signal output if a Traceable vent tube is detected while passing through the sensing zone.

Click Here for FVTDS documents + resources.

High Speed RFID Traceable Components

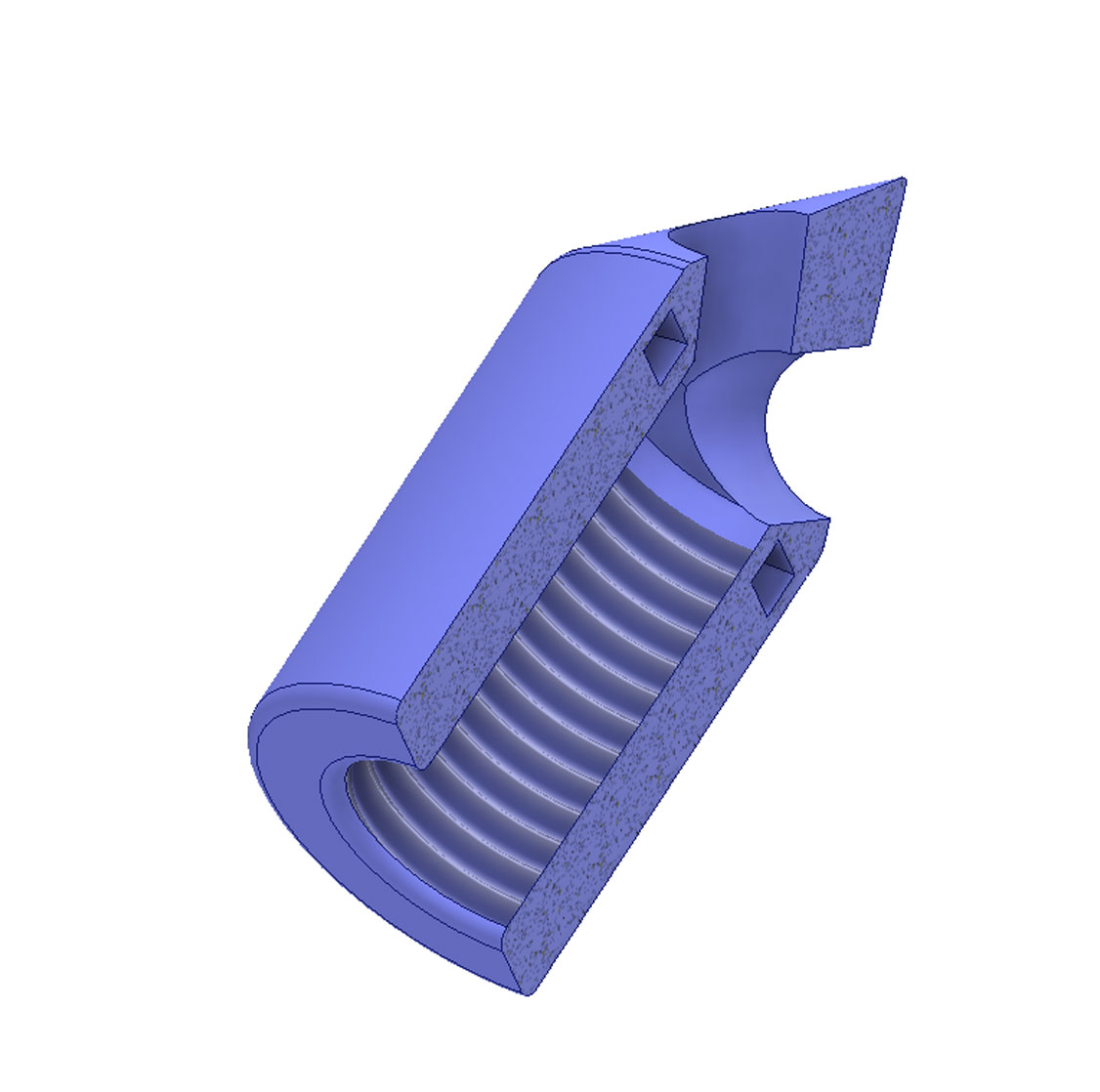

HIGH SPEED RFID TRACEABLE VENT TUBES (TVT)

The Enpro Traceable Vent Tube is a patented highly engineered traceable vent tube. When the TVT is used in conjunction with the Enpro Filler Vent Tube Reader (FVTR), all vent tube malfunctions are instantly detected.

The TVT uses passive technology to communicate data, provide traceability, detect malfunctions, or relay other custom information specified by the filling machine owner to the FVTR.

The TVT is constructed from food-contact-grade materials and designed for superior durability.

Click Here for High Speed RFID Traceable Vent Tube documents + resources.

HIGH SPEED RFID TRACEABLE VENT TUBE Tips

The TVT uses passive technology to communicate data, provide traceability, detect malfunctions, or relay other custom information specified by the filling machine owner to the FVTR.

The TVT is constructed from food-contact-grade materials and designed for superior durability.

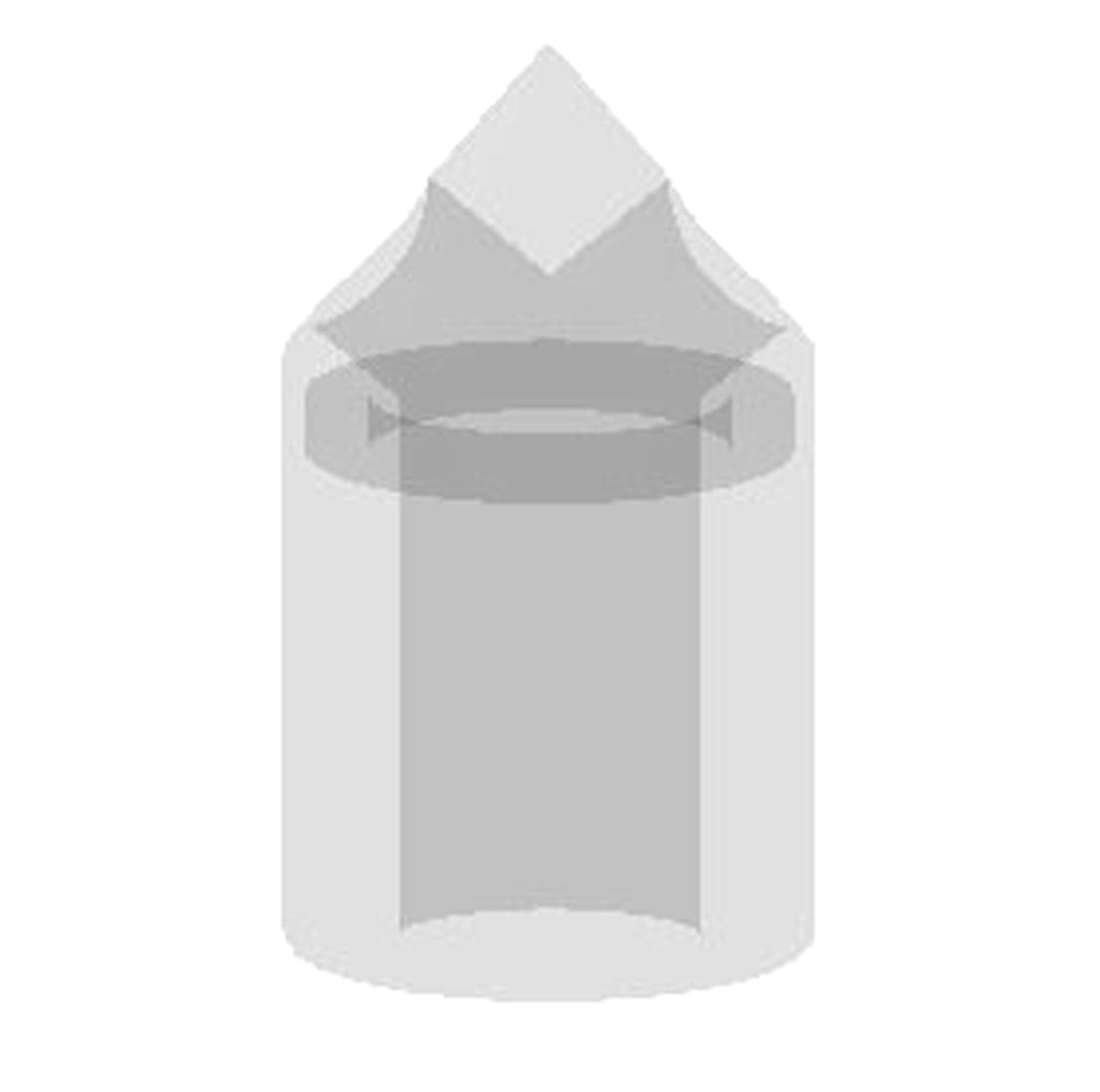

HIGH SPEED RFID TRACEABLE Ball Cage (TBC) Assembly

The Enpro Traceable Ball Cage is a patented highly engineered traceable ball cage. When the TBC is used in conjunction with the Enpro Filler Vent Tube Reader (FVTR), all vent tube malfunctions are instantly detected.

The TBC uses passive technology to communicate data, provide traceability, detect malfunctions or other custom information specified by the filling machine owner to the FVTR.

The TBC is constructed from food contact grade materials and designed for superior durability. The TBC is constructed from food contact grade materials.

Click Here for High Speed RFID Traceable Ball Cage documents + resources.

High Speed RFID TOOLS

Enpro Handheld High Speed RFID Vent Tube Reader

The Enpro FVTRP-HHR Handheld Vent Tube Reader is a portable lightweight testing instrument built to detect the custom RFID chip set of a vent tube with easy-to-see green LED indication of passing result.

Click Here for Enpro Handheld High Speed RFID Vent Tube Reader documents + resources.

High Speed RFID Vent Tube Strength Tester

The Enpro FVTRP-QCT QC Vent Tube Strength Tester is a portable hard case testing station built to quality test the custom RFID chip set of a vent tube with PC based management software that allows for specific levels of Vent Tube Strength measurable and displayable for each Vent Tube.

Click Here for Enpro Handheld High Speed RFID Vent Tube Reader documents + resources.

Service + Support

Service and Support for your Enpro Filler Vent Tube System and Filling Vent Tube products and tools is provided exclusively by AmeriChem Systems Inc., a wholly owned subsidiary of Enpro, Inc.

Sales

Learn more how we can work together to help make your beverage filling process more efficient. Please fill out the form and we’ll get back to you as soon as possible.